|

February 13, 2011

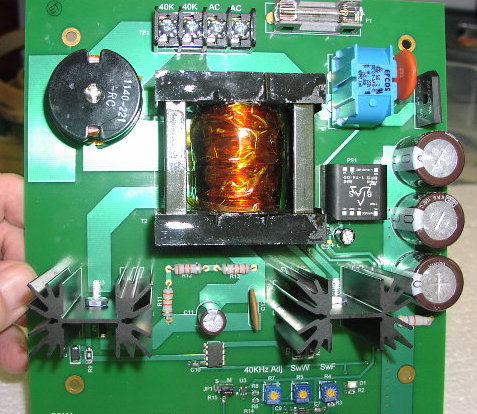

I got a frantic call from a company who builds powerful ultrasonic cleaning

machines. Their machines use banks of 50 watt piezoelectric 40KHz transducers.

Up to 6 can be driven by a single driver board. For years they were doing fine.

Then, for some reason the last batch of boards they were getting from their assembly house

were not working right. The units might work for a while but would then suddenly

stop. In each case one or more of the MOSFET power transistors which made up the

driver circuit would be shorted and the unit’s fuse would be open. They could not

figure out why these units were failing. |

|

|

40KHz

Ultrasound Cleaning Machine |

50 Watt 40KHz

Transducer |

|

|

The company sent me a documentation package, a cleaning machine, an old

working board and a few of the new boards. At first glance both board types looked

identical. I looked at the schematic. The 40KHz drive signal was created using a

pair of high voltage MOSETs, wired in a “push-pull” configuration. The transistors

drove the primary of a large ferrite transformer. The secondary of the transformer

drove the bank of transducers through a large ferrite pot core inductor. I measured

the inductance of the magnetic parts. Both the primary and secondary of the

transformers on the old and new boards matched. However, the inductance of the

series inductor in the new boards was quite a bit higher. Since this could be a

clue, I dug a bit deeper. The pot core inductance was designed to help match the

impedance of the transformer secondary to the complex impedance of the piezoelectric

transducers. The parallel capacitance of the transducers and the inductance of the

coil formed a series resonant circuit. In theory, the circuit should help generate a

cleaner near sine wave shape waveform.

|

300 Watt 40KHz

Transducer Driver Board |

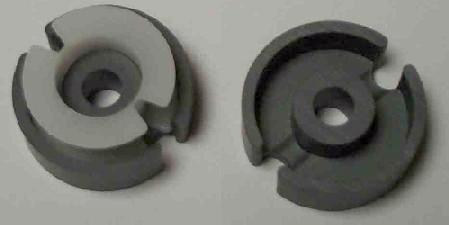

Pot Core with

Nylon Bobbin |

|

|

I unsoldered the pot core from both the working board and one of the new

boards. I carefully dismantled the two parts. When I pulled apart the core

from the new unit all I saw was a coil of magnet wire on a nylon bobbon, the two pot core

halves and a nylon screw to hold the assembly together. But, when I took apart the

old unit, out rolled a thin plastic washer slipped between the two pot core halves.

Bingo! The thin plastic washer between the core cups formed a small gap. Gaps are

often used to stabilize an inductance and more importantly in this circuit, helps prevent

core saturation. Every core has a maximum Amp-turns rating. If you exceed that

current, the core saturates and the inductance suddenly drops to a lower level. Now

it all made sense. If the core saturated, the peak current through the two FETs

would quickly spike, enough to exceed their rating and then puff, shorted transistors. I

told the company my findings and asked them to check the rest of the pot cores in some of

the new boards. Sure enough, all the units they checked did not contain the

thin plastic washer. As a final proof, I used an X-Acto knife and cut a piece of

plastic sheet of the right thickness and inserted into the pot core center. I then

re-soldered the now gapped core in one of the new boards sent to me and fired up the

machine. It worked perfectly.

It is too bad that all of these problems were caused by a thin piece of

plastic worth pennies but without it, this expensive piece of hardware would be worthless. |